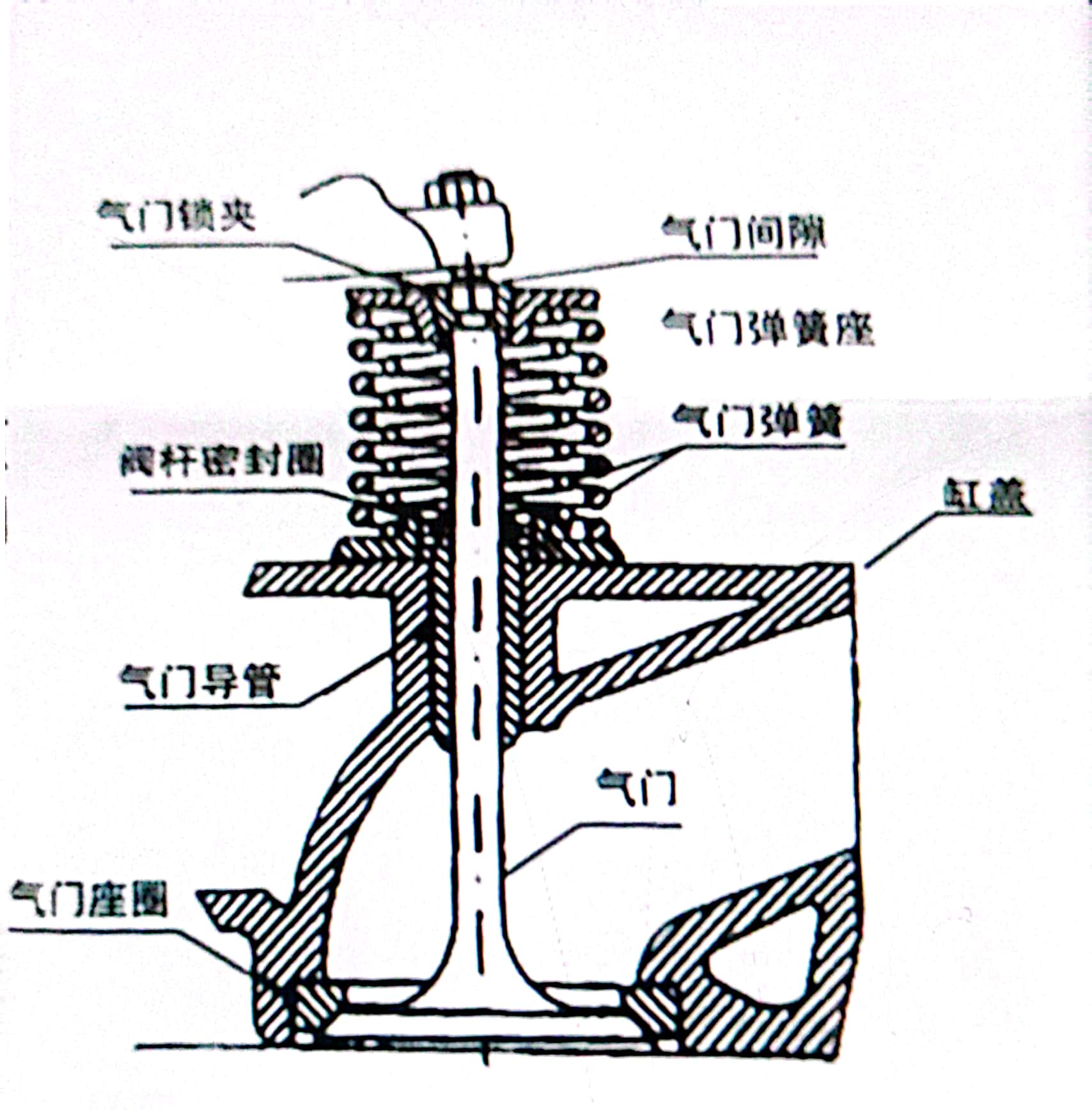

Valve installation-instructions for use

When the engine is working, the valve is subjected to strong mechanical stress, high temperature and chemical corrosion, which is an important part of the engine. It should be carefully unpacked and installed correctly. In the process of unpacking, assembling and using, it is not allowed to bump or be subjected to lateral force, otherwise the valve will be deformed, which will affect the valve seal and lead to early damage of the valve.

It is wise to replace the new valve when the engine is in maintenance. Even if the used valve has no surface defects, it may have invisible fatigue damage and cannot be used any more.

When replacing the valve, it is best to replace the valve guide and the valve spring at the same time. The old conduit will increase carbon deposition and oil consumption, and carbon deposition will lead to the increase of valve working temperature and affect valve service life. The old valve spring is harmful to valve service life and engine power due to the decrease of elastic force.

After the new guide tube is installed in the cylinder head, the reamer should be used to correct the roundness and inner hole size of the guide tube, so that the clearance between the valve stem and the guide tube hole conforms to the provisions of the engine manual. It is not allowed to process the finished valve stem. In use, the clearance between the valve stem and the guide tube hole must not exceed the wear limit specified in the engine manual, otherwise the valve or guide tube must be replaced, otherwise the valve will be damaged at an early stage.

For the deformed or burned valve seat ring, it must be hinged and ground for correction, and it cannot be repaired only by the method of grinding with the valve. The valve seat ring that can't be repaired should be replaced with a new one, and the repaired or replaced seat ring opening and the guide hole pipe should be coaxial, and the coaxiality should not exceed 0.03mm.. The position of the valve installed in the valve seat ring and the end face of the valve disc shall meet the requirements of the engine specification, and then be compared with the valve after meeting the above requirements.

The valve and the valve seat ring are gently studied to ensure the tightness of the valve. Do not use coarse abrasive when grinding. The contact part between the valve seat ring and the valve cone should be in the middle and lower part of the valve cone. The valve and seat ring must be well sealed, otherwise the engine power will be reduced and the valve will be damaged early.

After grinding, clean the abrasive with kerosene, and then lubricate the valve stem, seat ring and guide tube with clean engine oil.

Install new valve sealing ring.

Select qualified valve lock clips. If the lock clip is clamped, the diameter of the valve groove should be slightly studied, and there should be no bayonet phenomenon at the opening of the lock clip; Then put it into the valve spring retainer, so that the contact between the inner conical hole and the outer conical surface of the lock clip should be good.

When installing the valve lock clip, do not knock the end of the valve stem, and install it firmly, otherwise the valve will shake, causing the lock clip to bite the valve slot neck, which will cause the valve lock clip slot neck to break in use.

Adjust the valve clearance. The correct valve clearance is very important and must be adjusted according to the engine instructions. It's best to recalibrate once after the car has traveled 800-1000 kilometers. A small valve clearance will increase the working temperature of the valve; a large valve clearance will increase the impact of the valve. In both cases, the valve will be damaged early.

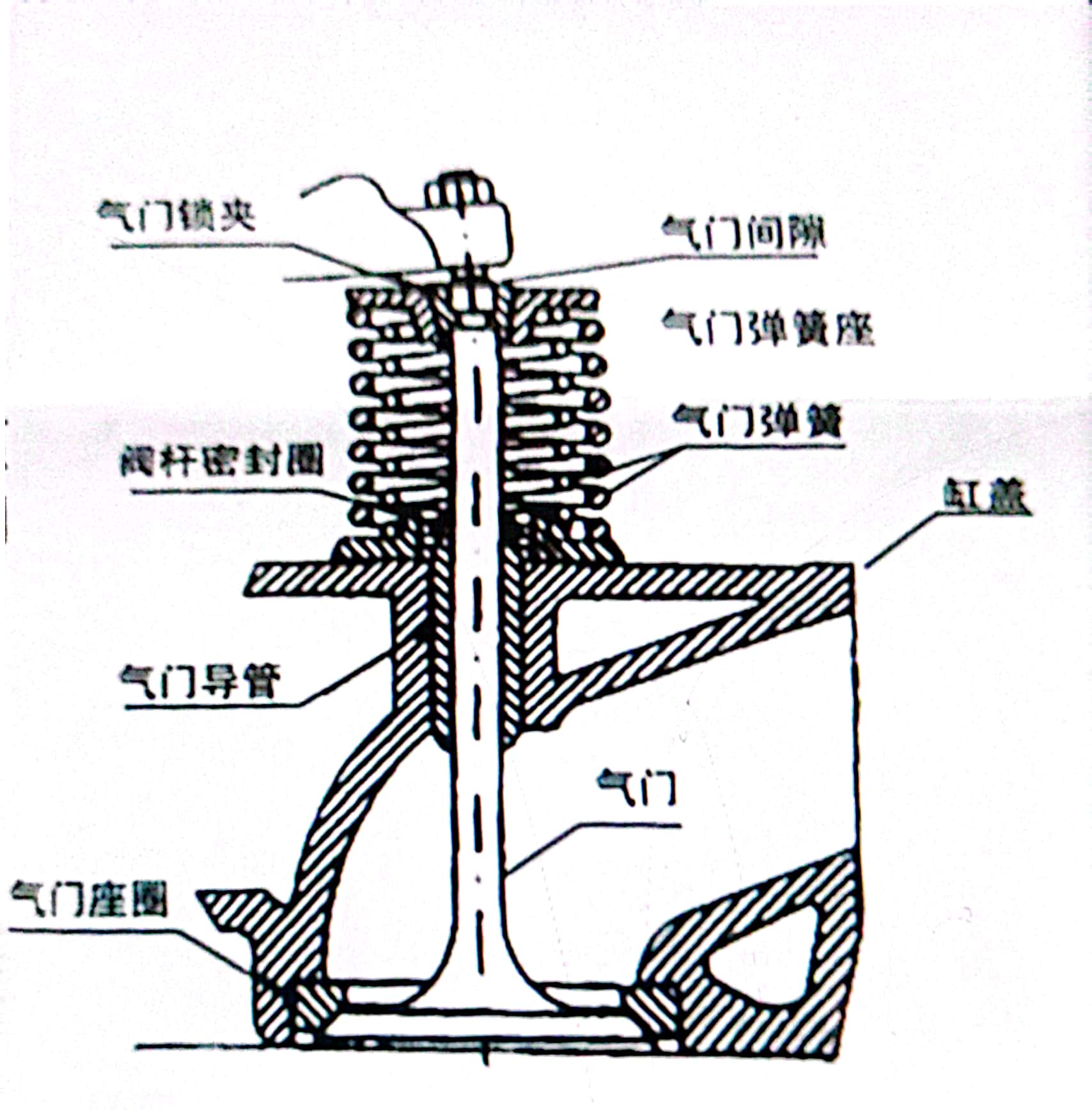

When the engine is working, the valve is subjected to strong mechanical stress, high temperature and chemical corrosion, which is an important part of the engine. It should be carefully unpacked and installed correctly. In the process of unpacking, assembling and using, it is not allowed to bump or be subjected to lateral force, otherwise the valve will be deformed, which will affect the valve seal and lead to early damage of the valve.

It is wise to replace the new valve when the engine is in maintenance. Even if the used valve has no surface defects, it may have invisible fatigue damage and cannot be used any more.

When replacing the valve, it is best to replace the valve guide and the valve spring at the same time. The old conduit will increase carbon deposition and oil consumption, and carbon deposition will lead to the increase of valve working temperature and affect valve service life. The old valve spring is harmful to valve service life and engine power due to the decrease of elastic force.

After the new guide tube is installed in the cylinder head, the reamer should be used to correct the roundness and inner hole size of the guide tube, so that the clearance between the valve stem and the guide tube hole conforms to the provisions of the engine manual. It is not allowed to process the finished valve stem. In use, the clearance between the valve stem and the guide tube hole must not exceed the wear limit specified in the engine manual, otherwise the valve or guide tube must be replaced, otherwise the valve will be damaged at an early stage.

For the deformed or burned valve seat ring, it must be hinged and ground for correction, and it cannot be repaired only by the method of grinding with the valve. The valve seat ring that can't be repaired should be replaced with a new one, and the repaired or replaced seat ring opening and the guide hole pipe should be coaxial, and the coaxiality should not exceed 0.03mm.. The position of the valve installed in the valve seat ring and the end face of the valve disc shall meet the requirements of the engine specification, and then be compared with the valve after meeting the above requirements.

The valve and the valve seat ring are gently studied to ensure the tightness of the valve. Do not use coarse abrasive when grinding. The contact part between the valve seat ring and the valve cone should be in the middle and lower part of the valve cone. The valve and seat ring must be well sealed, otherwise the engine power will be reduced and the valve will be damaged early.

After grinding, clean the abrasive with kerosene, and then lubricate the valve stem, seat ring and guide tube with clean engine oil.

Install new valve sealing ring.

Select qualified valve lock clips. If the lock clip is clamped, the diameter of the valve groove should be slightly studied, and there should be no bayonet phenomenon at the opening of the lock clip; Then put it into the valve spring retainer, so that the contact between the inner conical hole and the outer conical surface of the lock clip should be good.

When installing the valve lock clip, do not knock the end of the valve stem, and install it firmly, otherwise the valve will shake, causing the lock clip to bite the valve slot neck, which will cause the valve lock clip slot neck to break in use.

Adjust the valve clearance. The correct valve clearance is very important and must be adjusted according to the engine instructions. It's best to recalibrate once after the car has traveled 800-1000 kilometers. A small valve clearance will increase the working temperature of the valve; a large valve clearance will increase the impact of the valve. In both cases, the valve will be damaged early.